|

PLEASE NOTE ..... This Page covers both =

Purchased Brands & My "Homemade" All Scratch Built - Electronic Speed

Control. And Normally I build my own versions,

but I also buy - manufactured brands and the

following - below info, should help you

choose a system for your model - a lot more easily. So from this

point, I'll refer to all "Speed Controls" as simply an - SPDC .... Or

abbreviated term, to make things = easier.

Purchasing The Right "SPDC"

Can be confusing!

Tap

Photos To Enlarge

Rule # 1 ...

The Novice or Beginner .... should be aware that a lot

of manufactures, use a wide assortment of confusing terms, like Maximum

Current Load ... Peak Current Or Peak Power Load or Peak Voltage and

other terms or phrases to convince you their system is better than

another. And they also claim their systems are usually the best, or

better over all others. And some even show charts that indicate

they're products out perform a competitors. So you have to be

careful, especially when many systems don't spell everything out, in

plain terms - that we can all understand. So you have to look - at

what their systems are designed to be used for. And then determine

what models, fit your needs and this usually is a choice among speed

control systems, usually designed for Race Cars & Trucks or Airplanes -

in most cases. That's

because these area's are much more popular parts of our hobby, and those

SPDC's are designed to run those types of models. And they aren't

built for model boats, but some usually will say they - will work, but

often won't. An SPDC used in a model workboat, requires a wider

operating range. That's, in order to provide the model with scale

speeds and realistic operations and more precise control.

So most SPDC's - won't work, because they can't handle long periods at

slow speed. Because this causes - Heat, to build-up in the SPDC and

causes it to blow fuses or worse = Burn Out. Extended long periods of

high current, meaning a model boat being operated - at slow speeds over

a long time period, finds the SPDC's are also further effected by summer

heat. And a lot of other factors beside this, can determine - if a

particular SPDC, can truly handle the job. And it has to provide

proportional - control ( Varied Speeds = 0 to Full Throttle = in

Forward & Reverse ), which some SPDC's only offer Forward Control, or

Low, Medium & Fast = Speeds,

in either direction.

Factor # One ....

How much "True Current = Total Amperage ... will your

motor ('s) draw or need?

Factor # Two ....

Is the Motor - Gear Driven or Not? Gear Drives -

reduce current loads on everything, including the SPDC, Motor &

Battery. Plus - they slow the model - down,

to more realistic scale speeds, which means it handles much better.

And this is something you need in a model Workboat. Cause =

Tugs - Ain't Supposed To FLY!....

Unlike some think, because the Worlds Largest - Tug, has just over

12,000 horsepower from its twin V-20 EMD Engines and only does a maximum

speed of 18 knots = with a tailwind & her ears - Pinned Back!

Factor # Three .... How Large is the

"Prop or Wheel" = Meaning Its

Diameter? The Larger - it Is, the more current load it will

demand and draw from the motor, the SPDC & the battery. Including the

amount of Pitch - the propeller has, which can effect this.

Factor # Four ....

How much does the Model -

Weight? Once built, with all the components installed = Motors,

Battery, Radio & Systems", the heavier the model, the slower it will

move and the more force it will require, to get moving. Here, this

issue - can be a plus, because a heavy model, handles more realistic.

But requires a bigger - SPDC, Motor & Battery to operate, so there are

trade-off's. And the bigger the boat,

the higher the cost - for all things related!

Factor # Five ....

What Kind of Boat - Is IT? ... Meaning -

Tugboat?, Cabin cruiser?, Battle Ship?, Submarine - "Or What???"

Because here, the idea is to match, as closely as possible, the scale

speeds and mannerisms of the real thing. The closer you get to a

matching things in scale, the cheaper the model will becomes in overall

costs, because you aren't buying more than is required ... Sorta

Makes Sense - Huh $$$!

_______________________________________________________________

Types Of SPDC'S

# 1 ... Basic "On/Off" = Switch .......

Including two speed - types, which reduce the voltage & current loads,

by using "Wire Wound Resistor" or Basic High Load - Resistors, to allow

a High & Low Speed function. "May or May Not" offer direction control

of the motor. Often used in Race Boats or R/C Cars & Trucks.....NOTE

= Doesn't work well for model boats - unless its a Race Boat!

( AVOID THESE THINGS )

- unless the unit is used as a switch for turning

- On/Off some option inside the model = Pump, Winch or Bow Thruster -

for example!

# 2 ... Wire Wound - Resistor Types .......

( May or May - Not ), provide "Reverse & Forward" Direction control

functions, but does offer - Variable Speeds, from 0 to Full Power, in

usually ranges of 3 to 12 volts!

....

A waste of $$$ - in my opinion,

because their easily burnt out.

"Sorry - DUMAS ...... "Your SPDC - Is One Of The Worst!"

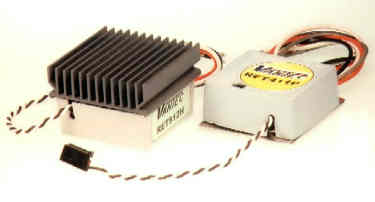

# 3 ... Electronic - Variable Types = requires no

Servo ....

These systems simply plug directly into the radio - receiver, and use

digital or pulse frequency signals from the transmitter, to control the

motors "Direction & Speeds", via the radios - throttle stick

position. Here the throttle when set to its - Center Position, causes

the motor to stop. And by moving the throttle control - in either

direction ( Up or down ), it gives the motor its variable speeds in

either direction = Forward or Reverse from a crawl to full speed.

These units also handle 3 to 12 volts or Larger Voltages, with much

Higher Current Loads. Their basic size, is usually close to size of a

common pack of cigarettes, with heavy "Heat Sinks" to dissipate the heat

- away from their transistors.

When I buy an SPDC -

its a VANTEC, because their

heavily built = Yes, their a bit more expensive, but well worth every

penny! Their built to withstand very heavy current loads and lots of

abuse, so you don't have to worry - as much about "Smoking IT = Burning

It Out!" Check them out - their simply the best brand of speed

control around and far more dependable, and a lot less troublesome than

other brand. Want proof?.....I've bought used Vantec's from friends

that used then in Race Boats, after they owned then for 5 or 6 years and

they still worked great!!

When I buy an SPDC -

its a VANTEC, because their

heavily built = Yes, their a bit more expensive, but well worth every

penny! Their built to withstand very heavy current loads and lots of

abuse, so you don't have to worry - as much about "Smoking IT = Burning

It Out!" Check them out - their simply the best brand of speed

control around and far more dependable, and a lot less troublesome than

other brand. Want proof?.....I've bought used Vantec's from friends

that used then in Race Boats, after they owned then for 5 or 6 years and

they still worked great!!

_______________________________________________________________

Current LoadS

Really Do Matter!

WARNING ..... Slow Speed,

for any electrically powered model, is the hardest thing to handle and

overcome. Because it means the SPDC, is being forced to handle a

large amount of current, for a much longer time period....... "When a

model boat is running at very slow speeds, this builds-up heat in the

transistors, which must be dissipated through the " Heat Sink Plates",

to keep the transistors cool. And this is where usually most SPDC'S =

fail in model Workboats, or others like; Warships, Subs & Cargo

Ships. Because they need a much heavier built - SPDC System, in order

to operate realistically at such slow speeds. In other words, the

slower you run, and the longer you do this, the more heat and load your

putting on the SPDC, like when your maneuvering - a barge into a dock,

for example. The longer this takes to accomplish, "The Hotter the

SPDC - Gets!"......So its gotta be designed to take this kind of abuse!

So the SPDC - has to be heavier and rated higher

to handle extended periods of continuous use. And here is where many

SPDC's Fail to hold up to the tasks your require of them. So their

maximum current ratings, may say they will take 100 amps for 20 seconds,

but they can't even handle 2 Amps, for 3 minuets, and therefore overheat

and fail. And because a

battery doesn't like its output - reduced, it always wants to provide

every last drop - it has, at Full Voltage & Full Current Load. So the

SPDC has to hold all this energy - back ( Sort Of ), which allows you to

run the motor, at various Speeds = Slow or Fast, or anything in

between! ( I Know this isn't true- Electronic Theory - You Electronic

Experts Out There, But bare with me here, we all ain't Electronic

Literate! ).

Generally speaking, a Tug or

Towboat, if working barges for example, does a lot of "Close-In" dock

work. Or has to maneuver another vessel - Very Slowly, in order to

avoid damaging it. Such a scale model must always try to mimic

realistically, what the real things can do and this means gentle - on

the controls, which electronics' circuits don't like to provide.

Unless you spend some money to build things so they -Do, and there are

many ways of doing it, but only one - Right Way! And power transistors

are designed to take - "Just So-Much Heat", before they Shut Down or

BLOW. The larger they are, the higher the cost and harder to replace

& repair. And using big - dc motors

that draw high current, in a model, is an added wasted in extra current

load..... In my opinion. Because it forces you to buy higher costing

SPDC's to handle things and that cost ya $$$$$

Even Nature,

gets its Licks-IN!

Always keep in mind, the weather

- itself and seasonal temperatures, also vary heat factors on the

SPDC. So it may work fine in the Spring - for example, then overload

and Burn-Out later, during hotter weather. So this is also an

important factor to include in choosing the right brand of SPDC or its

size of system, which may or may not be suited to your needs!

Still Not Sure, What To

Buy?

# 1 ...

Try This - have a buddy with his model tugboat, run his

model around the pond for a few minuets - at very slow speeds. That -

Is, provided the model is similar to what you plan to build? And it

has the same systems you may have to plan on using. Meaning Motor,

drives, battery, SPDC - Etc. By asking him to run the model for a few

moments - at slow speeds, bring it to the dock and check the heat on the

SPDC.....By touching it. if its really hot

enough to burns yer fingers, then buy a slightly larger system,

just to be on the safe side, if the manufacture of the SPDC- offers a

larger version? If they don't, then try to find a better brand of

SPDC and Regardless of whether its the same brand, or another slightly

higher priced and larger overall, your saving a lot of headaches.

# 2 ... Or ask

club members to assist you, if they run models - similar to your

project.

# 3 ... Or just go buy a VANTEC = SPDC and choose one of their

larger "High Quality" ... Heavy Duty SPDC systems, on my -

Modeler links page!

_______________________________________________________________

BUILDING Homemade

-

Electronic Speed Controls

Designed for 3 - 12

Volt DC & Motors Rated up to 5 Amps.

"Not For Use - In Speed & Race Boats!"

"Building Cost" =

Approx. $25.00 - per system!

............. Designed by - Old River - Bill Zumwalt

System Provides - Variable

Speeds = Reverse / Forward Functions. And requires a slight

conversion to your - r/c radio, to operate the SPDC. But does no harm

to the r/c radio, and can be later returned to normal operations.

This is my own unique

SPDC - design, that I've used to operate many of my "All Scratch - Model

Towboats". Its - well tested and proven - by many, for its rather

simple & cheap - costs, yet it provides what higher costing - purchased

systems do. And it has options - they don't, even if it - does

requires a slight modification to your r/c radio - to operate it!

NOTICE .... The Required Radio - Transmitter

Modifications, don't harm the radio and be easily converted back - to

normal operations!

This system will also work a pair of the 6 volt - Dumas Motors, or a

pair of Dumas - 12 Volt motors .... "If they are "Gear Driven" to

reduce current loads! Virtually any type of small dc motor, with a

similar rating to Dumas motor types, works with this system. And

usually only requires 2 transistors to be used in the circuit. Or

only a single transistor - for tiny Dc Motors, and can be easily

equipped with several transistors to handle larger motor - loads too,

with up to as many as 6 transistors in the circuit. And if the number

of transistors in the circuit - are increased, their simply installed by

parallel wiring them into the circuit. Meaning you can make the Heat

Sink - with the transistors, a separate board that plugs into the rest

of the control - if you wish. That means the system could be built

with several Heat Sink - Boards, with different numbers of transistors,

to make the control function-able with most any motor and model in your

fleet!

ONE MORE UNIQUE

FACT ...... This system, if the D.P.D.T. Switch

is removed from the circuit, will make an excellent speed control, for a

radar drive or winch - motors, to slow them down!

_______________________________________________________________

Old River Bill's ...

Homemade Electronic SPDC

Tap To

Enlarge

Save & Print Instructions -

FIRST = Simply print this entire web page

out, so you have a copy of the instructions and info on my homemade =

SPDC. Then Save

The Drawing =

to a PC - File, or

one of your Floppy Disks

..... To Print The

Drawing - By Itself, or save the entire page - if you wish,

Simply Tap to Enlarge

The Drawing .... Then Set your Printer to "Landscape" settings, with

Paper Size - Settings on "Legal Sheets" = 8 1/2" x 14" Paper, when

printing this drawing

Save & Print Instructions -

FIRST = Simply print this entire web page

out, so you have a copy of the instructions and info on my homemade =

SPDC. Then Save

The Drawing =

to a PC - File, or

one of your Floppy Disks

..... To Print The

Drawing - By Itself, or save the entire page - if you wish,

Simply Tap to Enlarge

The Drawing .... Then Set your Printer to "Landscape" settings, with

Paper Size - Settings on "Legal Sheets" = 8 1/2" x 14" Paper, when

printing this drawing

This circuit can handle the additional

"HEAT BUILD-UP" that occurs in "Scaled Workboat", when running at

constant slow speeds = "Pushing & Pulling Barges" for example, in

towboats. This factor builds more heat into a Speed Control and often

makes them fail and this systems transistors will take a lot of

abuse. The Realism of RC Events demand - today, that models are

capable of handling true scale duties, like their Real Prototypes.

And many times a Modeler runs into problems, when a "Purchased" speed

control - Overheats, usually caused from by purchasing - to small a

system!

As - I've said,

this system is designed for - hard work, because it uses from "One to

Six" Transistors, as options, that you may need, for various types of

models or dc motors, to match the system to the current loads. So

this circuit can be enlarged, by simply mounting the units controls, =

on a separate circuit board, from the Transistors & their = Heat Sink

Plate". That way, you can make several "Transistor - Heat Sinks,"

with varied numbers of transistors, that just simply plug into the rest

of the circuit. That way, you always have a "PLUG - IN SYSTEM", to

handle whatever current loads - you may encounter. Plus you can

install the units into different model boats, without a lot of hassle

too!

REMEMBER -

"Slow Speed & Slow

Maneuvering" ....

Cause heat to build in electronic

speed circuits, which eventually causes most of them - to FAIL. While

this system - adds more transistors and increases its ratings, to

ensure it will handle the job. Its still cheaper to build than

purchased versions, and has most of same advantages, with only a couple

draw-backs. One, is trying to find some of the circuit components,

which the hardest - is, the 10 K Ohm Slider? This Item - I usually

find by junking out - volume controls or slide controls, from old worn

out "Walkman Stereo's" ... Old TV Sets, and other electronic

components. Removing their parts for use in my projects, which

provides me with lots of spare parts to build things.

So be sure to check out - Flea Markets and before you throw away an old

transistor radios / tape recorders or tape players, check their parts,

you might be throwing away things - you could use!

_______________________________________________________________

Homemade SPDC - Parts

List

#1 .... 2N 3055 - NPN

type Power Transistors ... ( 1 to 6 ) per - Speed Control ...........

"Radio Shack" - parts, and/or transistors with higher rating - if you

know what your doing!

#2 ... .1 MFD - Non -

polarized Capacitors .....( 2 Per Motor )...........................

"Radio Shack" - parts, used as RF Noise Suppressors on the DC Motor!

Solder one Cap lead - to each motor terminal, the other lead of the Cap,

to the Motor - Casing itself, to ground it. Polish the case, where

you locate the ground connections for the Caps, so the solder will weld

to the motor case!

#3 ... Mini -

Lever Switch .......(1) per - Speed Control ...Radio Shack # 275-016 -

"Caution when Soldering!"

They can easily be ruined, if heated - To Much, so buy a couple extras -

OK!!

#4 ... Fuse - 2 to 5

Amp. & Fuse Holder ..... (1) of each

...................................."Radio Shack" - parts

#5 ... D.P.D.T Push -

IN/OUT -- Soft Touch --Switch ....(4 Amp Rated) - ....Electronics Parts

Suppliers

#6 ... Aluminum Heat

Sink Plate - "Scrap Parts" or Purchased from Radio Shack or Other

Sources of Parts

#7 ... 10 K Ohm

Slider Control - (

Must have Slightly over 1"

Travel of Slide Length )... Most

Difficult Item to Find ... ( check Electronics Parts Suppliers )....

Or See Options

-Below!

#8 ... Stranded - 18 to

22 Gauge -- Multi Color Wire, or up to 14 Gauge Wire for "Large current

loads!"

#9 ... TEST EQUIP

= Additional Cost! (1) - 9 Volt Battery & 9 volt - Battery Plug with

leads. Plus (4) Alligator

Clips & ( 1 ) small "Cheap" 12

volt .. Mini - DC Motor, for testing the circuit.

You must also have a Multi Meter to check

the circuit - as well!

_______________________________________________________________

Testing The Circuit

A good quality "Multimeter" is needed for reading Volts / Ohms & Amps -

in total loads. Besides wire & solder, and of course - a Solder Gun,

or Solder Iron to assemble the system. Use a 9 volt battery to

operate the circuit - First, with a 9 Volt Battery - Plug equipped with

two - Alligator clips, along with that small dc motor - we mentioned

in the parts list. Connecting leads to the - Mini DC Motor and the

units - output side, of the circuit.

If you can vary the

speed of the mini motor, plus its directions too.... The circuit is

ready to be used with you models - motor and a larger battery.

NOTE.... Testing at

low voltage and low currents ( 9 Volts ) , avoids burnt out "Slider

Controls" or "Motors" ... If the circuit is wired incorrectly.

This circuit is designed to work different "Current loads" & various Dc

Motors, using from 1 to 6 transistors - "All Paralleled" together, in

order to handle larger amounts of HEAT or Current Loads!

Radio Shack - Motors or "Dumas" types or equivalent types - to them,

rated from 3 to 12 volts, with varied Current Loads ( from 1 to 5 Amps -

Max ), with the motors turning from 3,000 to 8,000 Rpm. That's what

this circuit was designed for, when used in model WORK BOATS, but it

will work in other model boats too...... As explained above, when

expanded or enlarged in transistor, beyond two or three transistors for

more typical usage!

OPTIONS =

Using

a SLIDER or POT - CONTROL

If you can't locate a 10 K Ohm "SLIDER", You can use a 10 K

"POT" ( Often called a

Common - Volume Control ) in

its place, available from any ELECTRONIC PARTS SUPPLIES. Adjusting

the components accordingly to the "Pot - Used", in its rotation or Swing

Angle ( See Drawings - for details )

Note - The Slider is the

best design - Method.

The Pot - puts a slight strain on the "SERVO" to make the unit switch -

Rev / For - directions, so use "Heavy Plastic" or "Brass" to make its

needed - 90 Degree style of "Bell Crank", for the Pot - Control Rod

Linkage!

_______________________________________________________________

Required - R/C

Transmitter = Conversion

For Using The "Homemade" SPDC

A

TWIN STICK = Futabe R/C Radio ... FIRST - Open the back of your -

Transmitter and locate the "Centering Spring" on the Throttle Control

Stick .... Then Remove It! This Does - No Harm to the radio and can

be replaced later, if its needed for another model or different type of

speed control, that needs this spring to work correctly. The only

thing the "Centering Spring" does, is return the "Gimbal Stick" to its

"CENTER" Most Position, when you release the Stick. That's where "Off

- Position" is located on this control function, so it allows Variable

Speeds and Rev / Forward functions.

A

TWIN STICK = Futabe R/C Radio ... FIRST - Open the back of your -

Transmitter and locate the "Centering Spring" on the Throttle Control

Stick .... Then Remove It! This Does - No Harm to the radio and can

be replaced later, if its needed for another model or different type of

speed control, that needs this spring to work correctly. The only

thing the "Centering Spring" does, is return the "Gimbal Stick" to its

"CENTER" Most Position, when you release the Stick. That's where "Off

- Position" is located on this control function, so it allows Variable

Speeds and Rev / Forward functions.

Warning ....

(( This homemade speed control -

won't work correctly, unless the radios throttle - "Centering Spring",

is removed! )) Adjust the Throttle Stick and Throttle "TRIM Control",

to Full DOWN Positions. Then adjust the Speed Control's ... "Servo"

Linkage, to its farthest point, UP against the Rev. / Forwd - D.P.D.T.

Switch. Make sure the D.P.D.T. Switch is "Pushed - In, so it will

switch - Directions properly. And allow a slight amount of Slack, to

avoid binding - the Servo, that controls the SPDC!

_______________________________________________________________

Operating The SPDC

To change directions = Rev /

Forward, simply pull the Transmitters - "Throttle Control" = Fully

"DOWN", to its Bottom Most Position ( with the Throttle - Trim, Also

pulled - fully Down ). Then move the Throttle Stick = "Upwards" to

vary the motor speed. Repeating this procedure, with the throttle

control = Again, will reverse the motors - direction! ( Adjust the

"Throttle - Trim" to allow the system to work the direction function, or

so it "Remains In - One Direction = Forward or Reverse - as you wish.

Note, by moving the TRIM Control to "Full Up" - Position, this also

gives a slightly - Faster Rpm Speed to the motor, like adding a "Turbo -

Charger" to your model! But will disengage the "Rev / Forward

Functions", until the Trim Co9ntrol is returned to its lowest position

again = fully down, for normal function.

I'll Add More - Later, so

check back Often!

_______________________________________________________________

Last Updated

On 06/29/23 .

With

|